ENC offers a variety of sound and vibration level surveys including ambient sound level measurements, operational sound level measurements, and noise analysis sound level measurements.

Ambient sound and vibration level measurements are taken before drilling activity, compressor operations, or any other oil and gas related activity begins at a proposed location to establish non-operational, or baseline, ambient sound levels. Many noise ordinances use the measured ambient sound levels to calculate allowable operational sound levels. For oil and gas operations that have already begun, ENC offers operational sound and vibration level measurements. Operational sound and vibration measurements can be used to verify compliance with allowable operational levels and also to demonstrate the noise impact of the oil and gas operations on the surrounding area.

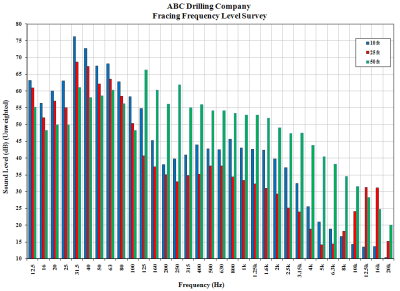

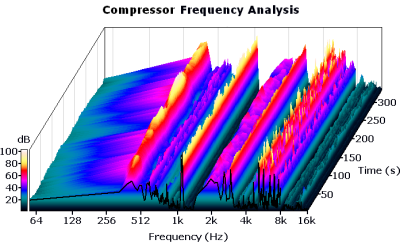

For occasions when oil and gas drilling sites, compressor stations, or pipeline excavation operations are in compliance with local ordinances and noise complaints are still streaming in, ENC offers a variety of noise analysis services that go beyond simple overall dBA sound level measurements. Using a combination of on-site audio recordings, detailed sound level measurements, and the PULSE analysis platform software developed by Brűel & Kjær, we are able to perform 1/1 and 1/3 octave band frequency analysis, and detailed 1/N octave fast Fourier Transform (FFT) and constant percentage band (CPB) frequency analysis.

We use detailed frequency analysis to identify pure tones, perform complex noise source identification, identify extreme low frequency (ELF) and infrasound, measure “frequency signatures” of noisy equipment, and recommend specialized noise mitigation material. Low frequency noise, infrasound, and pure tones are characteristics of noise that, when they are present, generally cause a high level of annoyance in humans. These characteristics can only be measured and identified with frequency analysis.

Noise source identification can be very difficult on oil and gas drill sites, compressor stations, or pipeline excavation sites because of the large number of noise generating equipment associated with such operations. Using detailed frequency analysis, ENC can measure the frequency spectrum, or “noise signature,” of each piece of equipment and compare it with the frequency spectrum at the location of the noise complaint to determine the offending piece of equipment. The frequency spectrums can then be used to select specialized noise mitigation material designed to block and absorbed frequencies particular to the noise generating equipment.

Contact Environmental Noise Control today for you vibration measurement, compressor noise measurement or drilling sound level testing before you begin drilling or if you have noise complaints. Request a quote today!